I. What is a Garment Storage Cabinet in a Cleanroom?

A Garment Storage Cabinet is a specialized cabinet designed for storing and preserving cleanroom garments such as coats, pants, hats, and shoes in a controlled contamination environment. Its main function is to control contamination, ensuring garments are kept in a clean condition and preventing dust, microorganisms, and other contaminants from affecting the stored apparel.

II. Operating Principle

A Garment Storage Cabinet operates on the principle of providing and maintaining a clean airflow inside the cabinet to protect garments from dust, bacteria, and other contaminants. This principle includes air filtration, pressure control, and air circulation to ensure the storage environment meets cleanroom standards.

III. Airflow Models

There are two common airflow types in Garment Storage Cabinets:

1. Vertical Laminar Flow

Clean air from the HEPA filter is blown directly from above.

Air moves downward through the garments and exits at the bottom or rear of the cabinet.

Maintains positive pressure, preventing contamination from the external environment.

2. Horizontal Laminar Flow

Clean air enters from the side and moves horizontally across the garments.

Used when top space is limited or when stronger front protection is required.

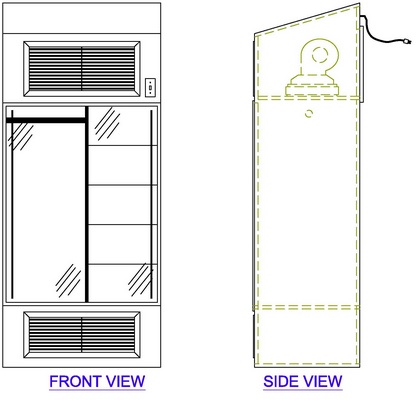

IV. Structure of a Garment Storage Cabinet

Garment Storage Cabinets typically include the following components:

1. Cabinet Body

Made from SUS304 stainless steel or electrostatic-painted steel (ESD).

Easy to clean, durable, dust-free, and resistant to cleanroom conditions.

2. Cabinet Doors

Made from tempered glass or transparent mica for easy interior visibility.

Airtight design to maintain positive pressure and prevent dust intrusion.

3. Air Filtration System (HEPA/ULPA)

Removes ultra-fine dust particles, meeting Class 100 or higher standards.

Ensures a continuous clean airflow inside the cabinet.

4. Clean Air Blower System

Provides positive pressure to prevent external dust and contamination.

5. Clothing and Shoe Storage

Includes stainless steel hanging rods, hooks, and shoe shelves for convenient storage.

6. UV Light or Sterilization System (Optional)

Helps eliminate bacteria, viruses, and mold, keeping garments sterile.

7. Control System and Sensors

Manages airflow speed, filter replacement alerts, and status indicators.

V. Types of Garment Storage Cabinets:

Garment Storage Cabinets are classified based on structure and functionality:

1. By Function:

Standard Cleanroom Garment Cabinet: Stores regular garments with HEPA filtration and clean airflow circulation.

UV Garment Cabinet: Equipped with UV lights for sterilization against bacteria, viruses, and mold.

Heated Garment Cabinet: Features drying functions to remove moisture and prevent mold growth.

2. By Material:

SUS304 Stainless Steel Cabinet: High durability, corrosion resistance, easy to clean, and withstands harsh environments.

ESD Painted Steel Cabinet: Lower cost but still ensures anti-static properties and easy cleaning.

3. By Storage Capacity:

* Small Cabinet:

- Storage Capacity: ≤ 20 garments

- Reference Dimensions (L x W x H):

900mm x 600mm x 1800mm

1000mm x 600mm x 1800mm

- Application: Suitable for small cleanrooms, laboratories, and low-staff production areas.

* Medium Cabinet:

- Storage Capacity: 20 - 50 garments

- Reference Dimensions (L x W x H):

1200mm x 600mm x 2000mm

- Application: Used in moderately staffed areas.

* Large Cabinet:

- Storage Capacity: More than 50 garments

- Reference Dimensions (L x W x H):

1600mm x 600mm x 2000mm

1600mm x 700mm x 2200mm

- Application: Suitable for large production areas, factories, and high-capacity garment storage.

VI. Contact Information

BACH LONG TRADING SERVICE MANUFACTURING CO., LTD

Address: 75 Nguyen Hong Street, Ward 1, Go Vap District, Ho Chi Minh City

Hotline: 093 143 54 54

Email: sales@congnghelockhi.vn

Website: www.congnghelockhi.vn