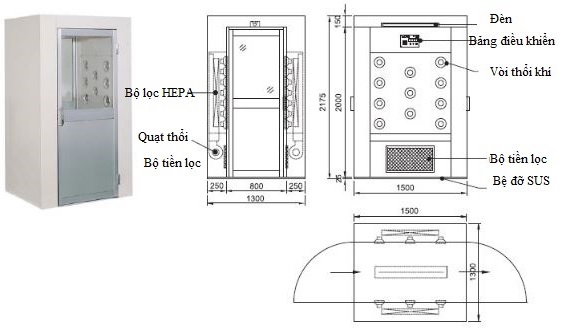

An Air Shower is a device installed at the entrance of a clean room to remove contaminants, dust from personnel, materials, and equipment before they are brought into the clean room. Air Showers are commonly used in electronics, chemical, medical, and pharmaceutical industries.

When someone enters the Air Shower, the system is activated by a sensor. Clean air, filtered through a HEPA filter, is blown out at high speed through nozzles mounted on the walls, removing 99.99% of dust particles as small as 0.3 microns. The air velocity ranges from 16-30 m/s. Contaminated air is sucked in through a vent at the bottom, filtered, and then recirculated.

Stainless Steel: Customers can choose from stainless steel 304, 201, 430, or 316 based on actual needs.

Electrostatic Powder Coated Steel: The electrostatic powder coating has a protective layer that prevents corrosion and oxidation.

HEPA Filter:

HEPA stands for High Efficiency Particulate Air Filter, which meets HEPA standards for air filtration efficiency.

The HEPA filter is made of ultra-fine glass fibers that can block many tiny particles in the air. The air passes through the dense filter, trapping pollutants through differential pressure. After passing through the filter, dust particles are retained at the filter's entrance. This process is repeated continuously, preventing dust particles from escaping back into the air. Fine dust particles as small as 0.3 microns (µm) are retained by the filter.

In typical Air Showers, HEPA H13 filters are used.

Pre-filter:

Pre-filters are used to capture coarse dust particles larger than 5 microns, typically made from synthetic fiber material.

Depending on thickness, they are classified as G2 (10mm), G3 (15mm), and G4 (20mm).

Centrifugal Fan: The required air velocity for Air Showers ranges from 16m/s to 30m/s. Therefore, fans are chosen for their compact size, large air volume, low noise, high air pressure, and easy installation.

Nozzle: Air nozzles, also called air shower nozzles, resemble a trumpet and are usually made of stainless steel, plastic, galvanized steel, aluminized steel, aluminum alloy, and other materials.

Manual Mode: The device operates based on programmed signals and parameters set by personnel, allowing for adjustments in air shower duration, lighting control, and emergency stop button.

Automatic Mode: The device operates based on preset signals and parameters without personnel intervention. The system adjusts its operation automatically based on factors like sensors, time, or other input signals.

Emergency Stop Button: Used in Air Showers for the following purposes:

Prevent Accidents: The emergency stop button allows operators or personnel to quickly halt machine operations in case of an emergency, preventing accidents and protecting human life.

Protect Equipment: During unexpected incidents, using the emergency stop button can protect machinery from significant damage due to abnormal operation.

Enhance Workplace Safety: The emergency stop button is essential in safety procedures, ensuring that workers can intervene quickly to reduce risks.

Simplify Operation: Designed for easy use even in emergencies, the button ensures that users do not need to remember complex procedures.

Improve Psychological Safety: The presence of an emergency stop button provides workers with a sense of security, knowing they have a means of immediate intervention when needed.

Legal Compliance: Many labor safety regulations and standards require the installation of emergency stop buttons on machinery and equipment, helping businesses comply with these regulations.

Pharmaceutical Industry: Medicines require high quality and absolute sterility. A standard air shower chamber helps keep medicines in optimal condition.

Cosmetics Manufacturing: Similar to the pharmaceutical industry, cosmetics also require standard air shower chambers to prevent chemical components from being contaminated with bacteria and dust.

Electronics Manufacturing: Electronics manufacturing demands absolute dust cleanliness, making Air Showers essential for producing high-quality electronic products.

Food Processing: Meeting food safety standards in processing and product quality is crucial for any establishment. Air Shower systems are among the best solutions in this field.

Medical Equipment Manufacturing and Treatment: Air Showers are also widely used in medical fields, limiting and isolating harmful pathogens in public spaces and protecting medical equipment.

| Type | Users | Material | Dimensions (mm) | Price (VND) |

|---|---|---|---|---|

| Single-door Air Shower | 1 – 2 people | Electrostatic steel | 1250x1000x2150 | 55,000,000 |

| L-shaped Air Shower | 1 – 2 people | Stainless Steel 304 | 1450x1000x2150 | 86,000,000 |

| Sliding-door Air Shower | 3 – 4 people | Stainless Steel 304 | 1450x2000x2150 | 210,000,000 |

| Rolling-door Air Shower | 1 – 2 people | Stainless Steel 304 | 1450x3000x2150 | 320,000,000 |

| Double-door Air Shower | 3 – 4 people | Stainless Steel 304 | 1450x2000x2050 | 160,000,000 |

| Single-door Air Shower | 1 – 2 people | Stainless Steel 201 | 1250x1000x2150 | 58,000,000 |

When selecting an Air Shower, customers should consider the following criteria:

Filtration Efficiency: Ensure the Air Shower uses HEPA or ULPA filters with high efficiency, removing at least 99.99% of dust particles as small as 0.3 microns.

Material: Choose Air Showers made of durable, corrosion-resistant materials like stainless steel 304 or electrostatic powder-coated steel.

Airflow and Static Pressure: Ensure the fan has sufficient airflow and static pressure to meet the Air Shower's requirements.

Size and Design: Choose an Air Shower with dimensions suitable for the space and usage needs. The design should ensure efficient operation and easy maintenance.

Control System: The Air Shower should have a smart control system, allowing for airflow speed and operation time adjustments.

Noise Level: Choose an Air Shower with low noise levels to ensure a comfortable working environment.

Energy Efficiency: Select an Air Shower with high energy efficiency to save electricity and reduce operating costs.

Warranty and After-sales Service: Ensure the supplier offers good warranty and after-sales service.

Bach Long Trading Production Service Co., Ltd.

Address: 75 Nguyen Hong Street, Ward 1, Go Vap District, Ho Chi Minh City

Hotline: 093 143 54 54

Email: sales@congnghelockhi.vn

Website: