1. What is a HEPA Box?

A HEPA filter box (HEPA Box) is an important device in the air handling system of clean rooms. It is designed to filter and remove dust, microorganisms, and other contaminants from the air before that air is supplied to the clean area.

2. Operating Principle:

Air from the external environment or from a non-clean area is drawn into the HEPA Box through the air intake openings.

As the air enters the filter box, it is directed through the HEPA filter. The HEPA filter is made from ultra-fine glass fibers arranged in a way that maximizes the surface area in contact with the air. This allows the filter to capture small particles and microorganisms (such as bacteria, viruses, pollen, fine dust, etc.) with an efficiency of up to 99.97% for particles measuring 0.3 micrometers (µm) or larger.

After the air has been filtered through the HEPA filter, clean air is pushed out of the box and supplied to the clean area or clean room through the air outlet openings.

To ensure optimal filtration performance, the HEPA filter needs to be regularly inspected and replaced when necessary. This helps maintain air quality in the clean room and ensures that contaminants are not released back into the environment.

3. Applications:

Pharmaceutical Industry:

The HEPA Box is used in pharmaceutical manufacturing plants to filter air in areas such as production rooms, compounding rooms, and packaging areas, ensuring that the air is clean and uncontaminated.

Food Industry:

In food processing facilities, HEPA Boxes help remove dust and microorganisms from the air, ensuring that food products are produced in a clean and safe environment.

Electronics Manufacturing:

HEPA Boxes are crucial in the production of electronic components, where dust and contamination can affect product performance. They are used to filter air in assembly and testing areas.

Healthcare:

In healthcare facilities, HEPA Boxes are used to maintain clean air in operating rooms, recovery rooms, and intensive care units, helping reduce the risk of infections for patients.

Laboratories:

Research laboratories, particularly in biology and chemistry, use HEPA Boxes to ensure that the air in the room remains clean, preventing cross-contamination between samples.

Biotechnology:

HEPA Boxes are used in the production processes of vaccines, stem cells, and other biological products to ensure a clean and safe environment.

Air Conditioning Systems:

In office buildings, hotels, or commercial facilities, HEPA Boxes can be integrated into air conditioning systems to improve indoor air quality, especially in areas with high occupancy.

4. Construction:

Main Frame: The frame of the HEPA Box is typically made from materials such as stainless steel 304, 201, 430 or electrostatically painted steel to ensure durability and corrosion resistance. The frame is designed to be airtight to prevent contaminated air from entering the clean area.

HEPA Filter: The HEPA filter is made from ultra-fine glass fibers arranged to optimize the surface area in contact with the air and has the ability to remove at least 99.97% of particles measuring 0.3 micrometers (µm) or larger, helping to block microorganisms, dirt, and other contaminants.

Air Regulating Damper: Located on top or on the side of the box, it helps accurately adjust airflow according to the clean room's requirements.

Hanging Hook: A sturdy design that allows for hanging the HEPA filter box from the ceiling of the clean room, ensuring safety and durability during use.

Air Diffuser: Helps adjust and distribute airflow into the box evenly, optimizing filtration efficiency.

DOP/PAO Measurement Port: Used to measure pressure differential to accurately and effectively test the performance of the HEPA filter.

Gel Containment Tray: Designed to enhance airtightness when air passes through the HEPA filter, ensuring no gas leakage.

Diffuser Plate: Helps evenly distribute clean air from the HEPA filter box throughout the clean room. With a grid or small hole design for even air dispersion. The diffuser plate ensures stable airflow, preventing vortex formation and facilitating the removal of particles from the clean room's airflow while maintaining filtration efficiency. The diffuser plate features even dispersion characteristics and a simple, aesthetically pleasing design that can be made in square or rectangular shapes depending on usage requirements. The diffuser plate can be detached from the outer frame for easy installation and cleaning.

Control System (if applicable): Some HEPA Boxes may be equipped with an automatic control system with sensors to monitor and adjust airflow, ensuring optimal filtration performance.

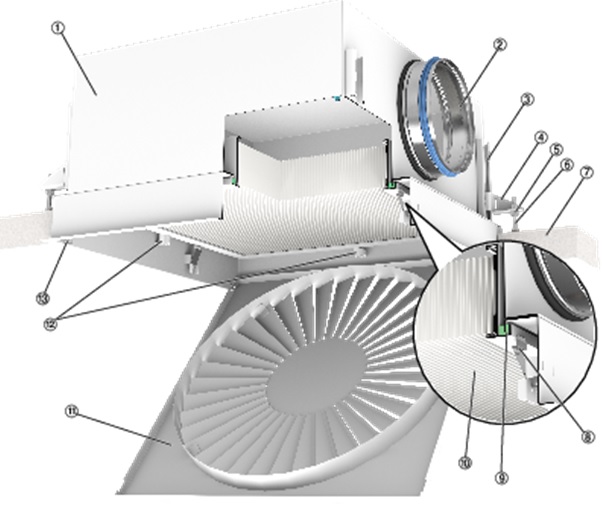

① Main frame ② Air neck (removable) ③ C-shaped rail for support

④ Hanging hook ⑤ Locking nut ⑥ Adjustment screw

⑦ Suspended ceiling ⑧ Retaining spring ⑨ Liquid seal

⑩ Filter ⑪ Air diffuser ⑫ Rotating clamp

⑬ Retaining magnet

5. Classification:

HEPA filter boxes are classified based on installation location and airflow status coming out of the box. By installation location, they are divided into Side HEPA Filter Boxes (installed on the side) and Top HEPA Filter Boxes (installed on the ceiling).

By airflow status, they are classified into Diffuser HEPA Filter Boxes and Axial Flow HEPA Filter Boxes. Among them, Diffuser HEPA Filter Boxes are usually preferred due to their ability to create uniform airflow within clean rooms.

6. Contact Information:

BACH LONG MANUFACTURING TRADING SERVICE CO., LTD

Address: 75 Nguyen Hong Street, Ward 1, Go Vap District, Ho Chi Minh City

Hotline: 093 143 54 54

Email: sales@congnghelockhi.vn

Website: www.congnghelockhi.vn