Clean Bench, also known as a laminar flow bench, is a cleanroom device used to control and prevent airborne dust and contaminants from sticking to or contaminating the items being used. Clean air passes through a high-efficiency air filter (HEPA filter) and is blown directly onto the items being worked on, maintaining a high level of cleanliness even in areas with lower cleanliness levels.

Clean Bench is equipped with glass doors or enclosed surfaces to create a closed workspace, allowing users to work inside without contaminating the clean air. The design of the Clean Bench ensures that clean air is evenly distributed over the entire work surface, optimizing performance and minimizing contamination risks.

Frame: Made of stainless steel or powder-coated steel, providing protection for internal components and durability for the device.

HEPA Filter: High-efficiency air filter (HEPA) capable of removing 99.97% of dust particles with a size of 0.3 µm, ensuring clean air is supplied to the work area.

Fan: The fan draws air from outside through the HEPA filter and blows clean air into the work area.

Lighting and UV Lamp: Fluorescent or LED lights are installed inside to provide sufficient illumination for the work area. In cases where there is a UV lamp, the UV lamp operates when staff are not working and is strictly controlled to ensure the safety of the operator.

Control Panel: The control panel allows users to easily adjust parameters such as fan speed, lighting, and other functions.

Work Surface: Usually made of stainless steel or corrosion-resistant material, easy to clean and disinfect.

Glass Panels: Transparent glass allows users to observe the work process inside without contaminating the work area.

Glass Door: Depending on customer choice.

Preparation of microbiological culture media: Clean Bench helps create a clean work environment free of dust and bacteria, ensuring that microbiological culture media plates are not contaminated during preparation.

Inoculation of microbiological samples: When inoculating microbiological samples onto culture plates, Clean Bench helps prevent the entry of bacteria and mold from the air, ensuring the accuracy and reliability of experimental results.

Preparation of cell culture media: Clean Bench is also used to prepare cell culture media, protecting cells from contamination and ensuring optimal culture conditions.

Handling sensitive biological samples: Clean Bench provides a clean work environment, protecting sensitive biological samples from contamination and ensuring the integrity of the samples.

Working with non-hazardous materials that require clean, particulate-free air: RNA/DNA.

Assembly of sterile equipment: Assembly of electronic devices.

| Criteria | Clean Bench | Biosafety Cabinet |

|---|---|---|

| Purpose | Provides a clean working area by filtering air through a HEPA filter, protecting the product from contamination. | Protects the user, the product, and the environment from harmful biological agents such as pathogens. |

| Scope of Protection | Only protects the product. | Protects the user, the product, and the surrounding environment. |

| Airflow | Uses laminar (unidirectional) airflow created from the top or back of the bench towards the user. | Air is drawn in through the front grille, filtered through the HEPA filter, and recirculated or safely exhausted. |

| Applications | Suitable for non-hazardous tasks such as assembling sterile equipment, handling non-infectious materials. | Applied in handling infectious agents, cell culture, and managing highly hazardous materials. |

Product protection: Clean Bench is designed to create a sterile work environment to protect the product from contamination. If your purpose is to ensure the safety of the user or to handle hazardous materials, you need to choose another type of cabinet (e.g., Biosafety Cabinet).

Type of Clean Bench:

Horizontal Laminar Flow vs. Vertical Laminar Flow:

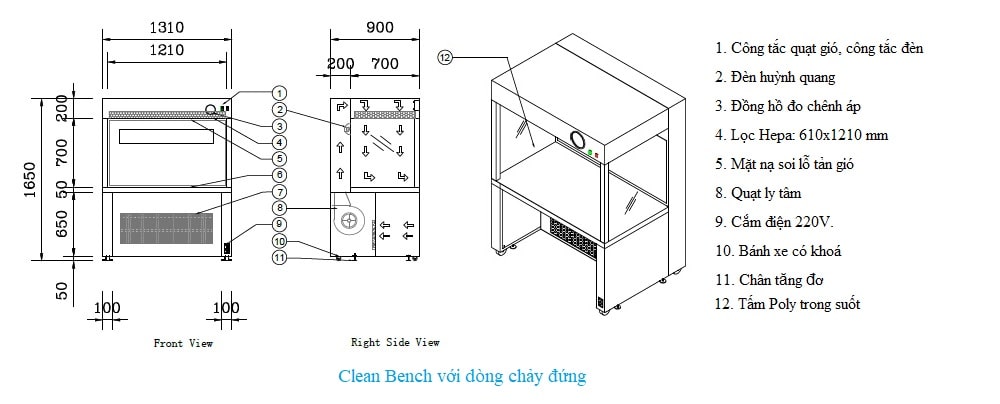

Clean Bench with vertical laminar flow typically allows air to flow from top to bottom, minimizing the impact of the operator's breath or movements on the product.

Clean Bench with horizontal laminar flow is often used in applications where a flat working space is needed and easy handling is required.

Performance and quality of the HEPA filter:

Check the technical specifications of the HEPA filter to ensure it meets filtration standards (usually an efficiency of ≥ 99.97% for particles sized 0.3 micrometers).

Attention should be paid to the lifespan and maintainability of the filter, as a clogged filter can reduce the effectiveness of the Clean Bench.

Airflow and uniformity:

Ensure that the Clean Bench has sufficient airflow and maintains uniform laminar flow across the entire work surface.

Uneven airflow can create contamination zones, affecting work results.

Size and design of the workbench:

Choose a Clean Bench with a suitable size to provide enough space for your operations and tools.

Flexible design and easy arrangement in the laboratory space are also important factors.

Material and durability:

Select a Clean Bench made of materials that can withstand frequent cleaning and resist corrosion, especially when using strong disinfectants.

Maintenance and operating costs:

Consider the ease of maintenance, replacement of the HEPA filter, as well as the long-term maintenance and operating costs of the equipment.

Check for after-sales service from the manufacturer or distributor to ensure timely technical support when needed.

Standards and certifications:

Ensure the Clean Bench meets international or national standards related to cleanrooms and product safety (such as ISO, GMP...).

These certifications will give you confidence in the performance and safety of the equipment.

Installation location and operating environment:

Install the Clean Bench in a stable environment, avoiding sources of interference such as windows, doors, or areas with strong airflow from other equipment.

Ensure the installation space allows the laminar airflow to operate efficiently without disruption.

CÔNG TY TNHH SẢN XUẤT THƯƠNG MẠI DỊCH VỤ BÁCH LONG

Address: 75 Nguyen Hong Street, Ward 1, Go Vap District, Ho Chi Minh City

Hotline: 093 143 54 54

Email: sales@congnghelockhi.vn

Website: