I. What is BFU?

BFU (Blower Filter Unit) is an air filtration device used in cleanrooms to remove dust, bacteria, and ultra-fine particles using an integrated HEPA/ULPA filtration system. The BFU includes a fan that draws in air and directly supplies clean air to the room, ensuring cleanliness standards required by various industries such as pharmaceuticals, electronics, food, healthcare, and biotechnology.

II. Operating Principle:

The BFU operates by drawing in air from the surrounding environment, passing it through a HEPA or ULPA filter to remove ultra-fine dust particles, and then supplying a stable flow of clean air to the controlled area. This device helps maintain positive pressure in the cleanroom, preventing contamination from external air.

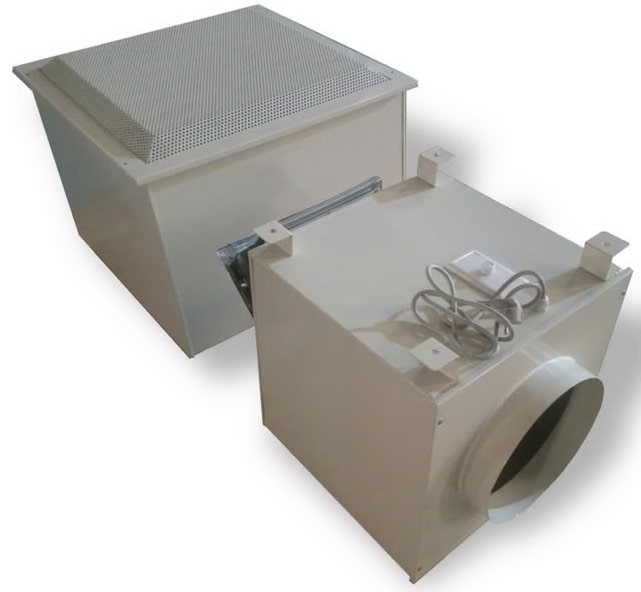

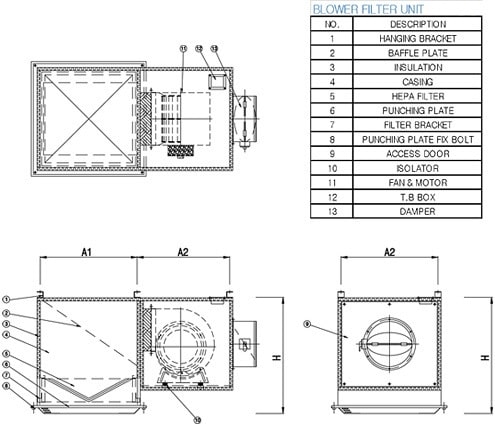

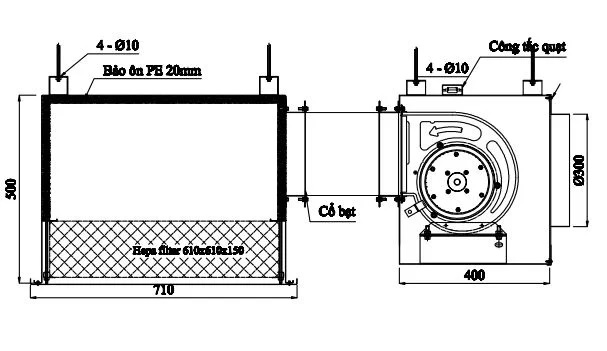

III. Structure of BFU:

Blower (Fan): Generates airflow through the filter.

HEPA/ULPA Filter: Removes dust and bacteria from the air.

Dampers: Reduce noise during operation.

Housing: Made of stainless steel or powder-coated aluminum to prevent dust accumulation.

Control System: Adjusts airflow speed and monitors filtration performance.

IV. Types of BFU:

BFUs are classified based on:

Fan type: Centrifugal or axial fan BFUs.

Filter type: HEPA (removes 99.97% of particles ≥0.3μm) or ULPA (removes 99.9995% of particles ≥0.12μm).

Application: BFUs for cleanrooms, biosafety cabinets, or production lines.

V. Where is BFU Installed in a Cleanroom?

BFUs are typically installed in:

Cleanroom ceilings: Supplying clean air from above.

Laminar flow systems: Ensuring tightly controlled clean air flow.

Biosafety cabinets: Protecting users from bacteria and chemicals.

Clean workbenches: Used in electronics manufacturing or laboratories.

VI. Criteria for Selecting a BFU:

Fan power: Must meet required airflow.

Filter type: HEPA or ULPA, depending on cleanroom standards.

Size: Suitable for installation space.

Noise level: Ensuring quiet operation.

Cleanroom standards: ISO 5, ISO 6, ISO 7, etc.

VII. How to Use BFU in a Cleanroom:

Regular inspection: Ensuring filter efficiency.

Replacing filters when necessary: Prevent clogging and maintain performance.

Cleaning fans and housing: Keeping the environment clean and reducing contamination risks.

Monitoring pressure and airflow: Ensuring stable BFU operation.

VIII. Differences Between BFU and FFU:

| Criteria | BFU (Blower Filter Unit) | FFU (Fan Filter Unit) |

|---|---|---|

| Design | Includes a fan and filter, integrated with HVAC systems | Compact unit with a built-in fan and filter |

| Installation | Connected to duct systems or central HVAC | Independently installed in cleanroom ceilings or air cabinets |

| Airflow Adjustment | Controlled via HVAC system or air dampers | Directly adjustable airflow |

| Static Pressure | Higher, suitable for large duct systems | Lower, controls only a small area |

| Main Application | Large cleanrooms with HVAC, pharmaceuticals, semiconductors | Small cleanrooms, independent clean air areas, workstations |

| Flexibility | Requires supporting systems, less portable | Easy to install, move, and expand |

IX. When to Use BFU vs. FFU in a Cleanroom?

✔ Integrated with a central air handling unit (AHU) to enhance air filtration in certain areas. ✔ Requires high static pressure to ensure stable airflow through duct systems. ✔ Installed in ceiling systems with air ducts, needing large and evenly distributed airflow. ✔ Suitable for pharmaceutical industries, large cleanrooms, and semiconductor manufacturing requiring strict airflow control.

📌 BFU Applications:

Pharmaceutical cleanrooms meeting GMP standards.

Semiconductor and electronics component manufacturing cleanrooms.

Food, cosmetics, and medical device factories.

Large cleanrooms with central HVAC systems.

✔ No central air handling unit (AHU) but requires high-efficiency filtration. ✔ Needs a flexible, easy-to-install system that can be expanded without redesigning the entire HVAC system. ✔ Used in small cleanrooms, clean air cabinets, and microbiological workstations. ✔ Suitable for localized airflow control, e.g., directing clean air to a specific work area.

📌 FFU Applications:

Small electronics component cleanrooms (Class 100, Class 1000).

Clean workbenches, biosafety cabinets.

Microbiology and medical laboratories.

Areas requiring controlled airflow without modifying central HVAC systems.

X. Contact Information:

BACH LONG TRADING - SERVICE - MANUFACTURING COMPANY LIMITED

Address: 75 Nguyen Hong Street, Ward 1, Go Vap District, Ho Chi Minh City

Hotline: 093 143 54 54

Email: sales@congnghelockhi.vn

Website: www.congnghelockhi.vn