I. What is FFU?

FFU (Fan Filter Unit) is an air filtration device with an integrated fan, used in cleanrooms to provide clean airflow and control dust, bacteria, and other contaminants in the working environment. This device ensures that the environment meets cleanliness standards as required.

II. Operating Principle

The operating principle of FFU consists of the following main steps:

1. Drawing Air from the External Environment

FFU is installed in the ceiling of cleanrooms or areas requiring ultra-clean environments. The process begins when the internal fan of the FFU draws air from the ceiling or space above the device.

2. Air Filtration Through HEPA/ULPA Filters

The air drawn into the FFU is pushed through a HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filter. These filters can remove at least 99.97% of dust particles as small as 0.3 microns (for HEPA) or 99.999% of particles as small as 0.12 microns (for ULPA).

The HEPA filter operates based on three main mechanisms:

Interception: Medium-sized particles (0.3 - 1 micron) are captured when they come into direct contact with the filter fibers.

Impaction: Larger particles (over 1 micron) are unable to follow the airflow and are retained on the filter surface.

Diffusion: Ultra-small particles (below 0.3 microns) move randomly (Brownian motion), leading to more collisions with the filter fibers, thus being captured.

3. Providing Ultra-Clean Air

After filtration, the clean air is blown downward into the work area in two main forms:

Laminar Flow: The air moves uniformly and in parallel, maintaining an ultra-clean environment, suitable for cleanrooms with high cleanliness requirements (ISO 1-5).

Turbulent Flow: The air diffuses in multiple directions, commonly used in general cleanroom environments (ISO 6-9).

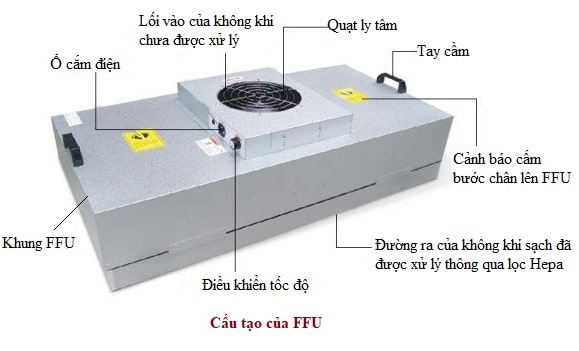

III. Structure

A Fan Filter Unit (FFU) consists of the following main components:

1. Housing

Made from galvanized steel, powder-coated steel, or stainless steel to protect internal components from external environmental impacts.

This material ensures durability, corrosion resistance, and compliance with stringent cleanroom requirements.

2. Fan

The fan generates pressure to push air through the filter.

It usually uses a DC or ECM motor to ensure quiet operation, high efficiency, and energy savings.

Helps maintain a stable airflow in cleanrooms, ensuring cleanliness according to ISO standards.

3. HEPA or ULPA Filter

HEPA Filter: Removes at least 99.97% of dust particles as small as 0.3 microns.

ULPA Filter: Higher efficiency, capable of removing 99.999% of dust particles as small as 0.12 microns.

This is the most critical component that filters out dust, bacteria, and airborne contaminants.

4. Control System

Allows users to adjust fan speed and turn the device on/off easily.

Users can select low, medium, or high airflow speeds depending on usage requirements.

Some advanced FFUs integrate air quality sensors to automatically adjust airflow.

5. Perforated Grill

The section where FFU draws air in before pushing it through the filter. It helps evenly distribute air, reduces resistance, and ensures stable filtration efficiency.

IV. Using FFU for Positive and Negative Pressure Rooms

1. FFU for Positive Pressure

FFU is used to create positive pressure when the goal is to keep clean air from being contaminated by the external environment. Positive pressure prevents dust, bacteria, and other pollutants from entering the cleanroom.

Applications:

Electronics and semiconductor manufacturing: Requires strict dust control to prevent product damage.

Hospital operating rooms: Prevents bacteria from entering sterile environments.

Pharmaceutical and food production: Ensures products are not cross-contaminated by airborne particles.

2. FFU for Negative Pressure

FFU creates negative pressure when it is necessary to control the spread of bacteria, viruses, or hazardous chemicals by preventing contaminated air from escaping. Air in the negative pressure room is filtered through a HEPA filter before being exhausted outside.

Applications:

Infectious disease isolation rooms (e.g., COVID-19, tuberculosis, severe flu, Ebola, etc.).

High-level biosafety laboratories (BSL-3, BSL-4).

Chemical and hazardous pharmaceutical production.

V. Differences Between Hepa Box and FFU

| Criteria | FFU (Fan Filter Unit) | Hepa Box |

|---|---|---|

| Structure | Integrated fan, HEPA/ULPA filter, housing, control system | Only HEPA filter, requires HVAC system for air supply |

| Principle | Fan draws air through HEPA filter and blows it into the cleanroom | Air is supplied from HVAC system, passing through Hepa Box before entering the cleanroom |

| Application | Cleanrooms without HVAC support | Cleanrooms requiring HVAC support |

| Installation | Ceiling-mounted, can operate independently | Connected to duct systems |

| Efficiency | Continuously supplies clean air independently | Depends on central air supply system |

Choosing the right FFU depends on various technical factors and usage requirements. Key criteria include:

1. Understanding Usage Needs

Cleanliness Requirements:

High Cleanliness Environments: Industries such as semiconductors, optics, and precision equipment manufacturing require strict particle control.

Standard Cleanrooms: Environments such as hospital operating rooms, laboratories, and pharmaceutical production require high filtration efficiency but with slightly lower cleanliness standards.

Environmental Control:

Temperature and humidity management (e.g., data centers, telecom rooms).

Noise Control:

Low-noise FFUs for offices, laboratories, and hospital rooms.

Special Requirements:

Anti-static capabilities for the electronics industry.

Optimized airflow distribution based on room layout and space.

2. Performance Considerations

Filtration efficiency: Choose between HEPA or ULPA filters.

Airflow and pressure: Determine based on room size and cleanliness level.

Noise level: Select low-noise FFUs.

Energy consumption: Opt for energy-efficient models to reduce operational costs.

3. Installation and Maintenance

Ease of installation: Simple design to reduce setup time and costs.

Filter replacement frequency: Ensure easy maintenance.

4. Application-Specific Selection

Manufacturing: High filtration efficiency, large airflow, low noise.

Hospital Operating Rooms: High filtration, low noise, easy cleaning.

Laboratories: Must effectively remove hazardous particles or gases.

Data Centers: Maintains stable temperature and humidity.

VII. Contact Information

BACH LONG TRADING AND SERVICE MANUFACTURING CO., LTD

Address: 75 Nguyen Hong Street, Ward 1, Go Vap District, Ho Chi Minh City, Vietnam

Hotline: 093 143 54 54

Email: sales@congnghelockhi.vn

Website: www.congnghelockhi.vn